Conger Technology

Solar Tensile Structures

PATENTED ALL TERRAIN SOLAR TECHNOLOGY

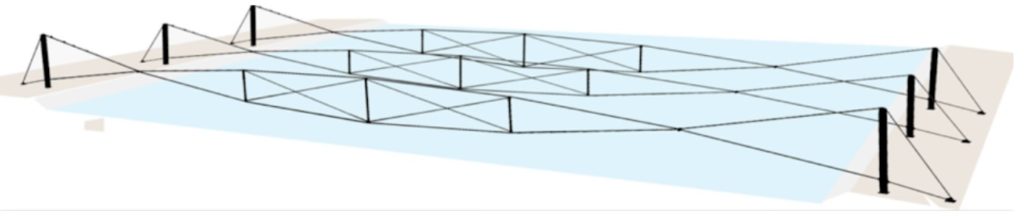

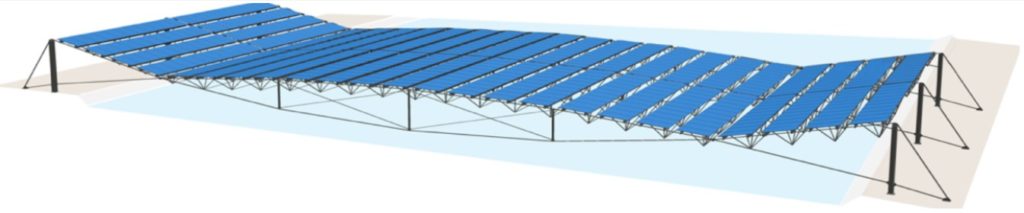

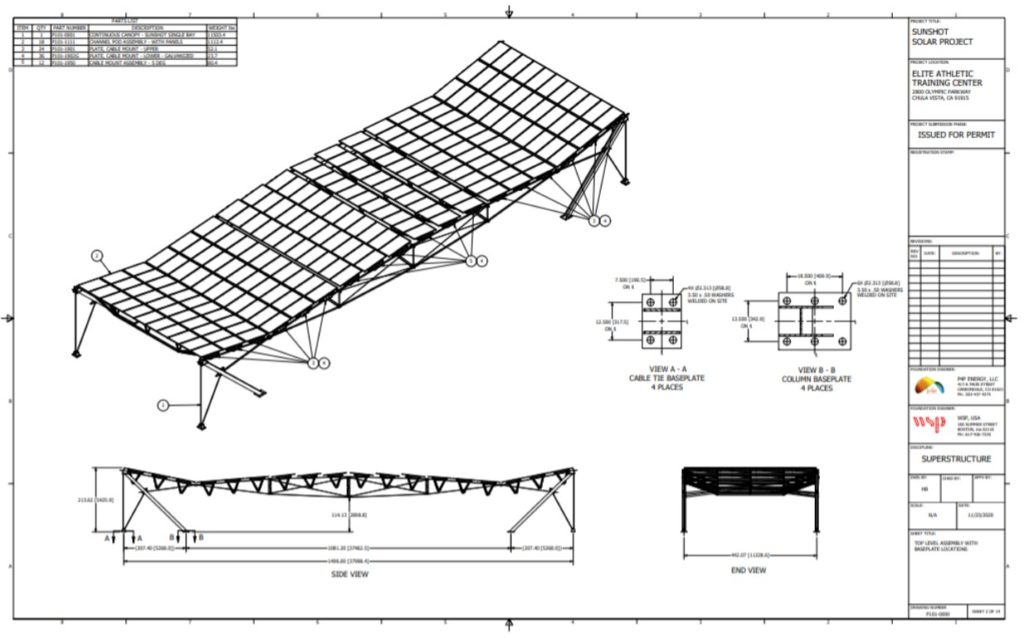

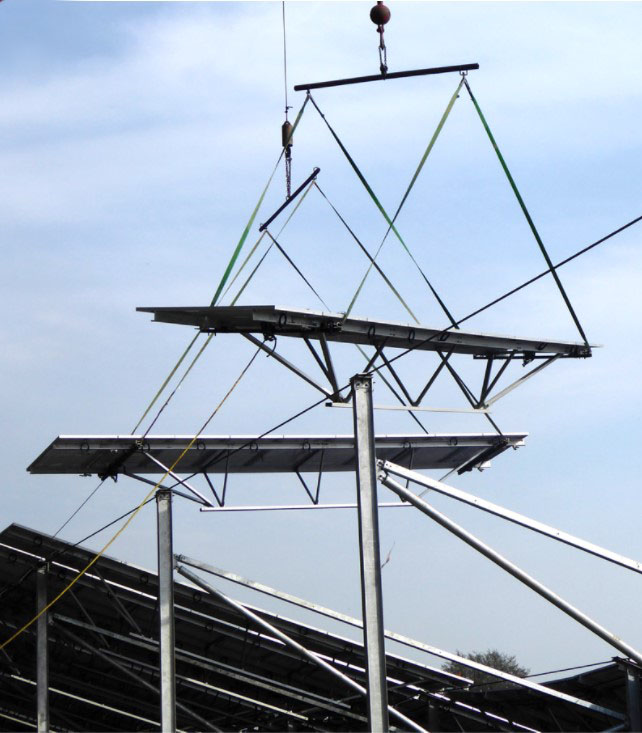

Conger Solar Systems’ patented PV panel suspension systems utilize tensioned steel cable technology to reduce cost and create entirely new solar applications. Conger Solar Systems’ incorporate the same tensile structure principles used in thousands of suspension bridges around the world to suspend solar panels over land already used for other purposes such as irrigation and water conveyance canals and parking lots. Conger solar systems also have application over agricultural fields and pastures, aquaculture (fish) farms, road and railways and unusable tough terrain and landfills. Our patented technology allows unparalleled versatility, enabling PV arrays to be supported at virtually any height over spans of up to 410 feet/125 meters. Conger Solar Systems are ultralight compared to traditional rigid structures which rely on significantly more steel to support the system, yet are structurally engineered to withstand hurricane force winds, seismic forces and winter snow loads.

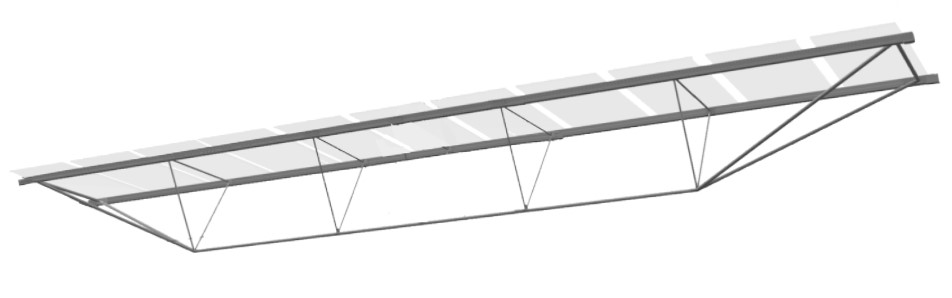

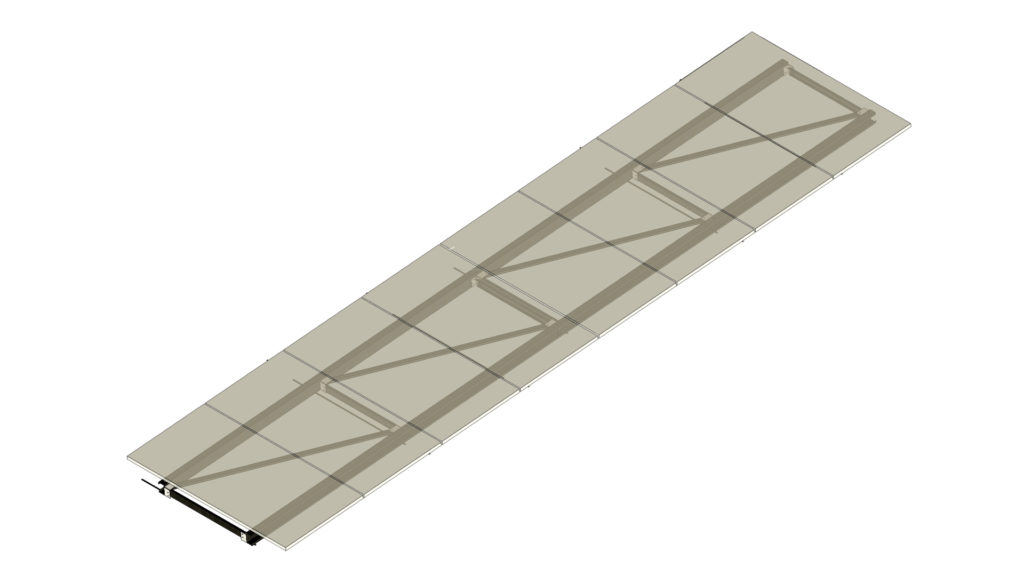

Underlying tensioned cable support structure

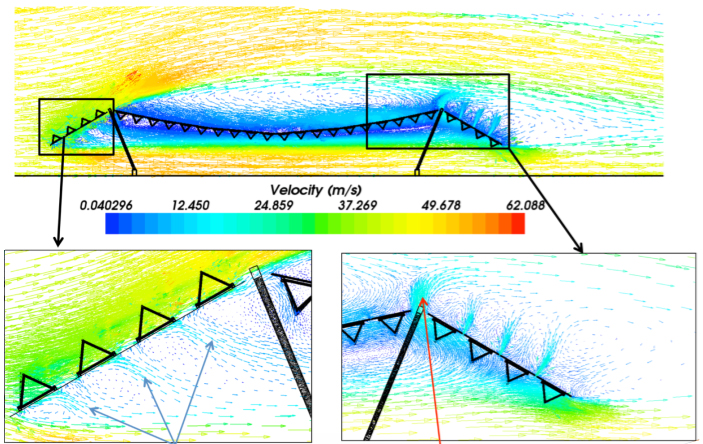

Conger structures are engineered using Computer Fluid Dynamics modeling to withstand asymmetrical, multi-directional, exponential wind forces

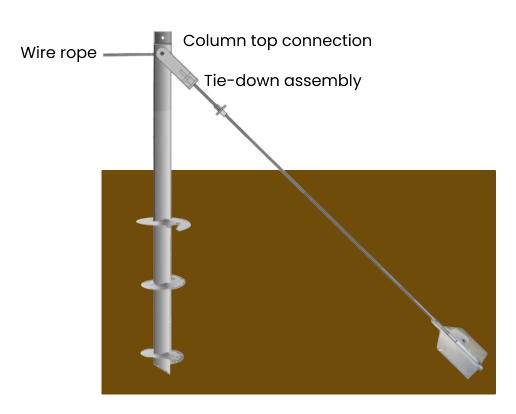

Helical Piers & Earth Anchors

SAVE TIME, SAVE MATERIAL, SAVE MONEY

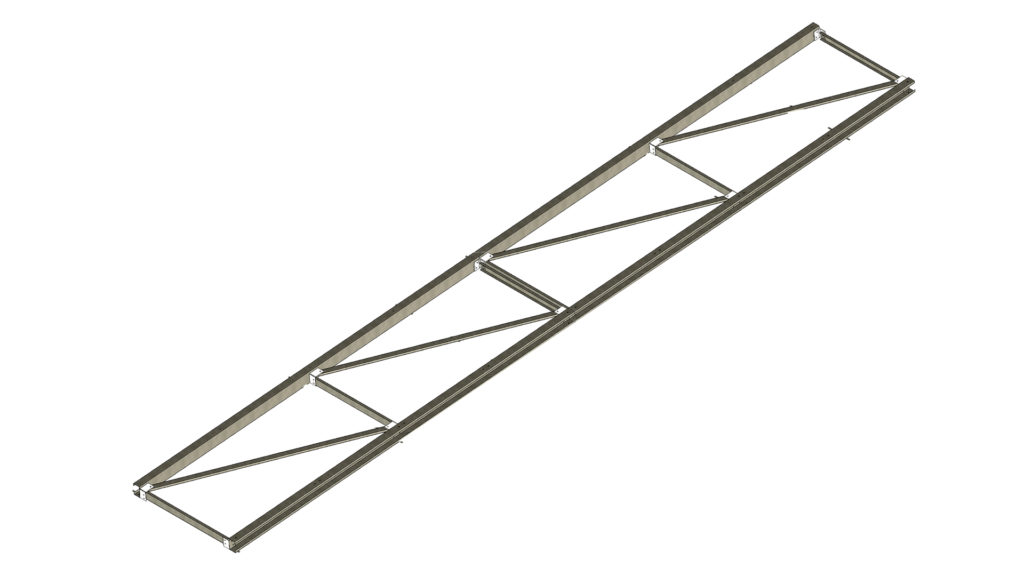

Space Frames

Standard space frame with pod and panels mounted

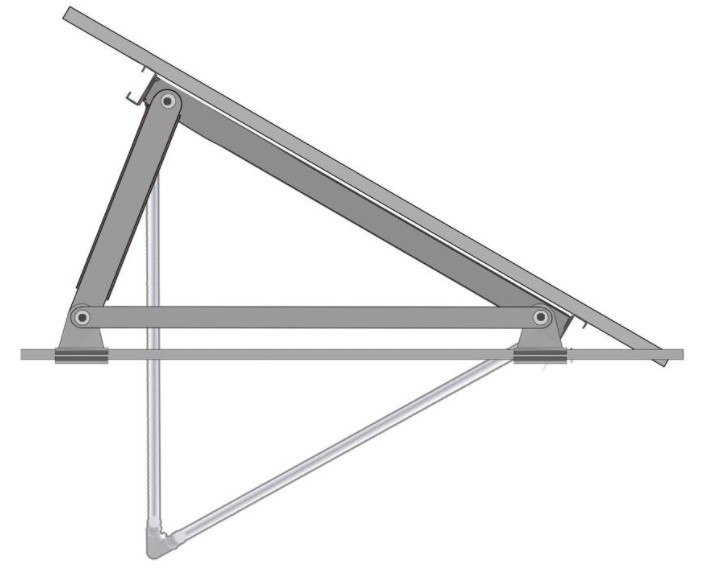

Angled space frame with pod and panels

Angled space frame with pod and panels (end view)

Pods

LIGHT, STRONG, FLEXIBLE

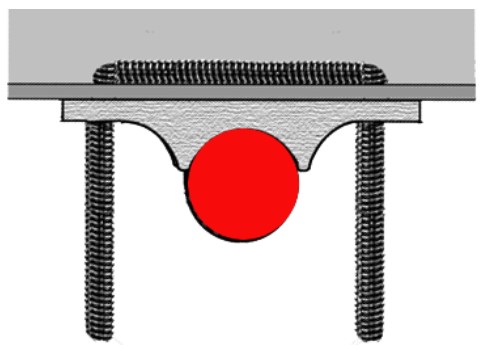

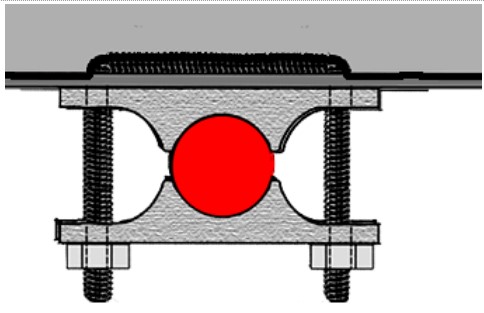

Cable Mounting Systems

Universal Panel-to-Pod Connectors

Single Axis Tracker

The Conger Advantage

Conger Solar Systems designs, engineers, builds and manages solar support structures that use 40% less steel and are installed in half the time of traditional, rigid support structures.

Low Cost Solution

The use of tensioned cables allows more weight to be supported using less material, creating inherently light, efficient, and cost-effective structures. The nature of the design also requires significantly fewer foundations (typically cement), reducing the environmental footprint and foundation cost. Cables are self-aligning and can be tensioned quickly with modern hydraulic tools, resulting in a fast and efficient construction process with significantly reduced labor costs.

Multiple Benefits Beyond Electricity Generation

Conger’s structures reduce solar system costs and do more than simply generate electricity. In addition to generating electricity to power the grid and pump and aerate water, Conger’s systems installed over land used for other purposes multiply infrastructure and land value by creating shade which saves water and increases crop yields and cools the planet. Conger Solar System’s unique technology can address multiple sustainability challenges with a single, cost-efficient technology capable of being applied at very large scale.

A research study recently conducted by several University of California professors concluded California could save 63,000,000,000 (billion) gallons of water if the state covered its canals with solar. The solar facilities over canals will generate approximately 14 GW of clean, renewable energy!